Classified Powershift hub proven to be over 99% efficient

Classified Powershift hub proven to be over 99% efficient

Using the most accurate test conditions ever seen in the bicycle industry, Classified proves that the Powershift hub is over 99% efficient in both the 1:1 and 0.7 gear ratios.

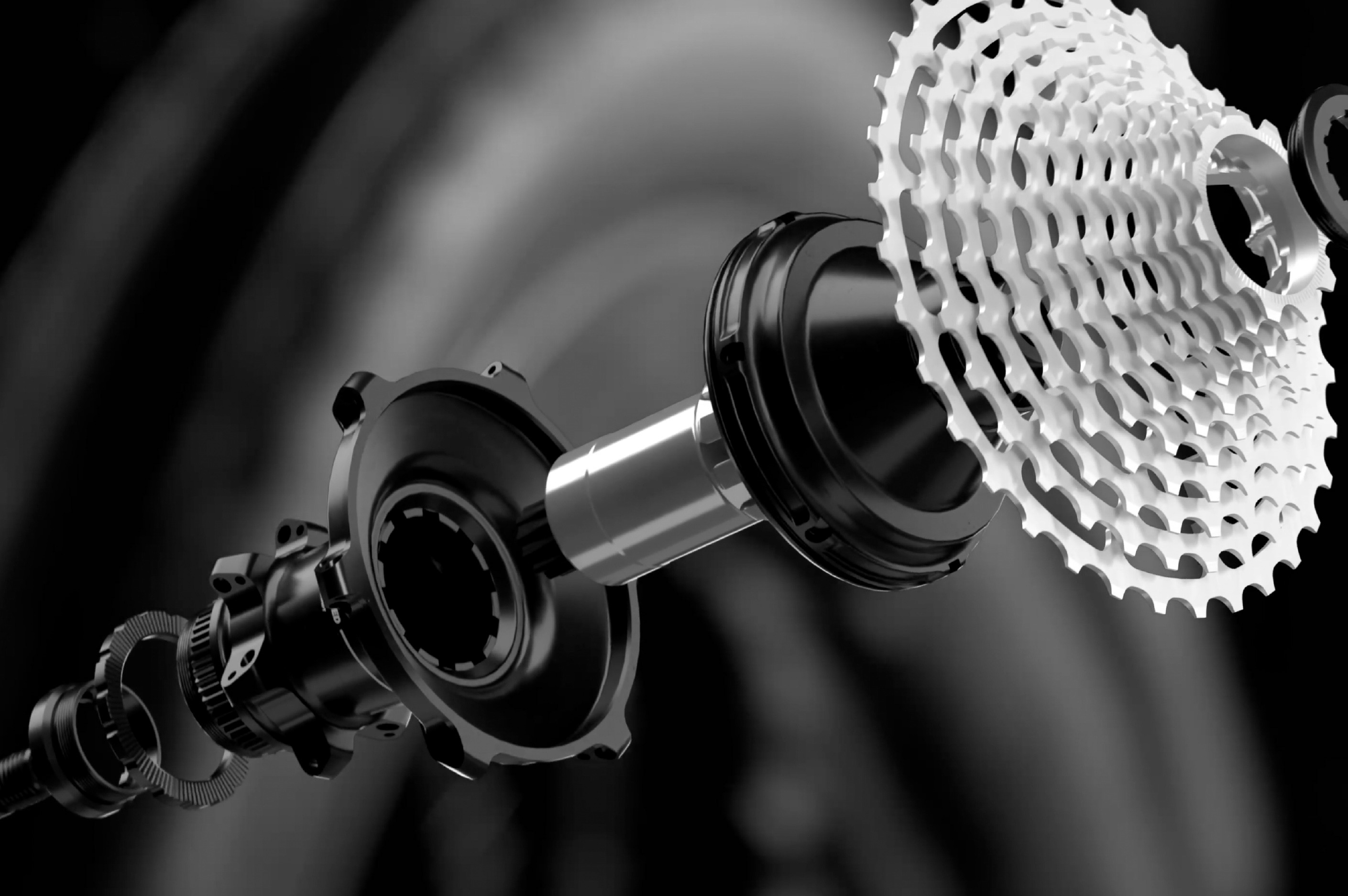

By removing the front derailleur and developing the Powershift hub, Classified set out to create a more reliable shifting experience by enhancing the control and functionality needed for optimal riding. The result is a more efficient and durable drivetrain solution.

Learn more about our efficiency results and testing here

The full white paper on our efficiency testing can be found here

Testing & Efficiency

Drawing on our experience in the automotive industry, Classified tested the Powershift hub to the highest standards, using a test rig specifically designed to measure power loss with a maximum error of 0.1%. The results of these tests show that the hub is 99.8% efficient in the 1:1 ratio, the same as a DT Swiss 240 hub (industry standard) measured on the same test rig, and 99.2% efficient in the 0.7 ratio, making it the most efficient internally geared hub ever created.

The efficiency of the Classified hub depends on the efficiency of the planetary gear. Planetary gearboxes have long been used in the automotive industry, with tests and computer simulations routinely recording gearbox efficiencies of 99% and above. References can be found in our white paper. With reliability and durability being the primary benefits of other multi-speed hubs (Rohloff, Sturmey Archer), the efficiency of a multi-speed hub has never been a primary design objective.

Classified is the first company to truly increase the efficiency of an internally geared hub.

An efficient planetary gear

At Classified we have used our expertise in automotive transmissions to maximise the efficiency of the planetary gear. We have increased the efficiency of the hub by using a small 0.6 tooth module, the most efficient planetary gear topology with the sun fixed to the axle, precision-made needle bearings and precision-machined gears. Unlike other multi-speed hubs, the Powershift hub uses only one set of planetary gears, maximising efficiency by design. This allows Classified to maximise the efficiency of Powershift Technology while keeping the weight of the planetary gear system low.

Learn more:

- Learn more about our Efficiency Data

- Read the full Efficiency White Paper

- Read the Classified Manifesto

- Read Classified's Origin Story

By removing the front derailleur and developing the Powershift hub, Classified set out to create a more reliable shifting experience by enhancing the control and functionality needed for optimal riding. The result is a more efficient and durable drivetrain solution.

Learn more about our efficiency results and testing here

The full white paper on our efficiency testing can be found here

Testing & Efficiency

Drawing on our experience in the automotive industry, Classified tested the Powershift hub to the highest standards, using a test rig specifically designed to measure power loss with a maximum error of 0.1%. The results of these tests show that the hub is 99.8% efficient in the 1:1 ratio, the same as a DT Swiss 240 hub (industry standard) measured on the same test rig, and 99.2% efficient in the 0.7 ratio, making it the most efficient internally geared hub ever created.

The efficiency of the Classified hub depends on the efficiency of the planetary gear. Planetary gearboxes have long been used in the automotive industry, with tests and computer simulations routinely recording gearbox efficiencies of 99% and above. References can be found in our white paper (below). With reliability and durability being the primary benefits of other multi-speed hubs (Rohloff, Sturmey Archer), the efficiency of a multi-speed hub has never been a primary design objective.

Classified is the first company to truly increase the efficiency of an internally geared hub.

An efficient planetary gear

At Classified we have used our expertise in automotive transmissions to maximise the efficiency of the planetary gear. We have increased the efficiency of the hub by using a small 0.6 tooth module, the most efficient planetary gear topology with the sun fixed to the axle, precision-made needle bearings and precision-machined gears. Unlike other multi-speed hubs, the Powershift hub uses only one set of planetary gears, maximising efficiency by design. This allows Classified to maximise the efficiency of Powershift Technology while keeping the weight of the planetary gear system low.

We invite you to read our efficiency data for yourself on one of the links below.

Learn more:

- Learn more about our Efficiency Data

- Read the full Efficiency White Paper

- Read the Classified Manifesto

- Read Classified's Origin Story

Updating the MTB Lexicon with a new verb:

to Power·shift [Powershifting] {Verb}:

(also: the new benchmark in shifting gears)

1. To shift gears under full load within 150 milliseconds

2. Maintain valuable momentum during climbs and transitions, or before an attack

Classified’s unique 2 speed gear hub allows riders to jump through 46% percent of the gear range, or the equivalent of 2 or 3 rear derailleur shifts, within 150 milliseconds. As such, ‘Powershifting’ is quickly becoming the go to term for maintaining momentum on the trails.

Tests undertaken with pro riders showed a far greater use of the powershift hub gear as opposed to the rear derailleur, leading to an overwhelming increase of momentum through transitions.

“The feedback of professional riders is very promising and brought us even better insights into the enormous potential the product offers. Extending our range further into off-road space with the mountain bike hub confirms Classified’s vision to be a technology that is compatible across all cycling disciplines. We are extremely excited about the possibilities the new product brings and its ability to enhance the existing MTB drivetrain market." says Mathias Plouvier, CEO and co-founder of Classified Cycling.

CTO Roell van Druten adds “we are very proud to bring Powershift technology to mountain biking. With an ultimate gear range of 530%, the Powershift Boost hub combines a high-grade, one-piece compact steel cassette (11-40t) with a larger chainring, improving the overall durability of the drivetrain.”

Van Druten goes further to explain the benefits of the new system: “Using the Classified hub with an 11-40t cassette and a 34t chainring results in the lowest drivetrain ratio of 0.58. To achieve this ratio with a traditional system the user would have to use a 30t chainring. Using a smaller chainring in a traditional system lowers the efficiency and durability of that system due to the higher chain forces. The more compact Classified cassette also allows the use of a shorter derailleur cage, increasing the robustness of the drivetrain alongside the efficiency.”

The Ringshifter:

The next generation of shifting, this sleek, fully wireless handlebar control provides unrivalled shifting performance with the lightest flick of your thumb. The Ringshifter can perform 10,000 shifts before needing to be easily recharged with the provided magnetic USB cable.

Featuring a unique magnetic spring back mechanism, the Ringshifter delivers unparalleled durability and a smooth, responsive feel. The functionalities of the Ringshifter can be customized to meet the individual needs of every rider.