News & Stories

-

Posted: April 17, 2024Read more »

Classified and ENVE announce partnership

Customers will be able to choose from a selection of road and gravel wheelsets along with a rolling chassis bicycle build, equipped with Classified’s pioneering internal hub shifting technology.

Classified Cycling will be bringing its proprietary internal hub shifting technology to carbon wheel and frame manufacturer ENVE’s premium products, giving ENVE customers access to new levels of performance on road and gravel.

The global partnership will see several ENVE wheel models outfitted with Classified’s Powershift hubshell. This enables riders to install the system and enjoy the gearing range and versatility offered by a 2x system but with the increased efficiency and aerodynamic advantages of a 1x, as well as the ability to shift under load, for more control. It will allow customers to build a bike from the wheels up with products including the MOG / Melee / Fray, Foundation, SES, and G Series. The system will also be available to purchase as a complete rolling chassis model, where consumers can select their bike build online or through ENVE’s dealer network. This includes options to fully integrate Classified’s Powershift technology with other selections

-

Posted: January 24, 2024Read more »

Increasing firepower of the gravel team - adding more riders & partners

Under the curious eyes of numerous spectators and cyclists at Velofollies, we unveiled our Factory Gravel Team.

The team, also backed by Ridley, is set to become the first professional factory team in the gravel discipline.

Classified entered the gravel circuit in 2023 as a one-man team with Dutchman Piotr Havik; shortly after Daan Grosemans joined the team during the season. Now the company is lending its name to an additional three British gravel talents: Brits Toby Perry, Annabel Fisher, and Freya Rawlins. -

Posted: January 19, 2024Read more »

Introducing the R36, R50 and G42 Carbon Wheelsets

We are excited to announce the release of our new wheelsets, enhancing the climbing, aero, and gravel riding experience. These meticulously designed wheelsets are outperforming market-leading brands in aerodynamic stability.

-

Posted: December 12, 2023Read more »

Classified Launches Mobile App

Offering seamless compatibility and effortless pairing, the new Classified app ensures easy updates and battery life visibility for the smooth running of all Classified products.

You can download the app now on the App Store or Play Store via this link.

-

Posted: November 02, 2023Read more »

Classified release new G42 Launch Edition gravel wheelset

Working with launching partners 3T and Ridley, the G42 Launch Edition is now available in very lmited quantities with the Exploro Racemax and Kanzo Fast Replica builds.

-

Posted: September 28, 2023Read more »

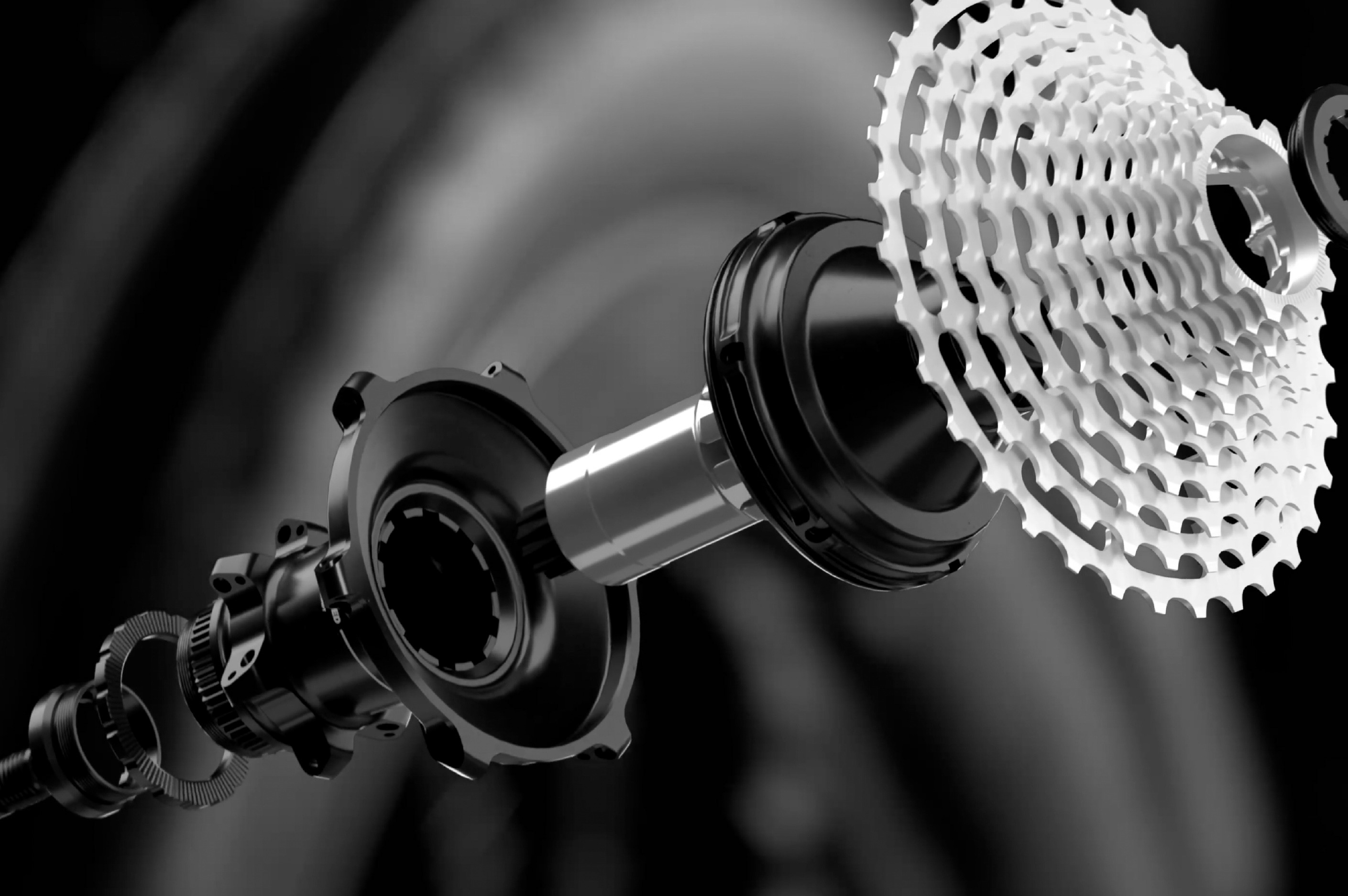

Classified Powershift hub proven to be over 99% efficient

Using the most accurate test conditions ever seen in the bicycle industry, Classified proves that the Powershift hub is over 99% efficient in both the 1:1 and 0.7 gear ratios.

By removing the front derailleur and developing the Powershift hub, Classified set out to create

-

Posted: September 25, 2023Read more »

Classified's Origin Story with Dr Roëll van Druten

Ever wondered when, where and how Classified's Powershift Technology came into being? We sat down with the inventor of Powershift Technology, Dr Roëll van Druten, to discuss the origins of Classified, the journey from inception in 2013 to today, and what motivated him to reimagine the drivetrain as we know it.

-

Posted: September 24, 2023Categories: MTB & GravelRead more »

Classified XC MTB x Dream Build - Win a Wheelset

Classified's XC MTB hub and wheelset has been given the Dream Build treatment, and to celebrate we're giving away a Powershift XC MTB hub and wheelset. Watch the video below and then enter the competition via the Classified Instagram account.

Working with the awesome Dream Build team, you

-

Posted: September 12, 2023Read more »

Test Powershift Technology at a Classified Event

Join us at one of the upcoming cycling events to meet the Classified team, test the instant shift of Powershift Technology for yourself, and learn about our partner and product updates.

-

Posted: September 05, 2023Read more »

Rob Britton Solos To Victory At Badlands 2023

Classified athlete smashes the course record, wining the 750km gravel race solo in a time of 35 hours and 20 minutes.

With an emphatic solo attack on day one of the race, Classified athlete Rob Britton soloed to victory at the Spanish gravel race, completing the gruelling 750km course in 38 hours

-

Posted: September 04, 2023Read more »

Completeing the Silk Road Mountain Race on a Classified Cargo Bike

Two weeks ago, ultra cyclist Allan Shaw completed one of the hardest off-road ultra endurance races on the planet - on a cargo bike! 1,800km and 30,000 metres of climbing, mostly on tough gravel and rock-strewn roads, we caught up with Allan after the dust had settled to discuss the race and how he got on with his Classified equipped Omnium cargo bike in such a difficult environment.

-

Posted: August 24, 2023Categories: Road, TT & TriRead more »

Classified athlete Kyle Smith wins Ironman Ireland 70.3

Racing Powershift Technology at Ireland's premier Triathlon event, Classified's Kyle Smith won the 70.3 distance race by over 8 minutes. Proving the efficicney of the Classified system, Smith's win is the first for Classified in Triathlon since launching just 2 months ago.

Classified: